Boiler

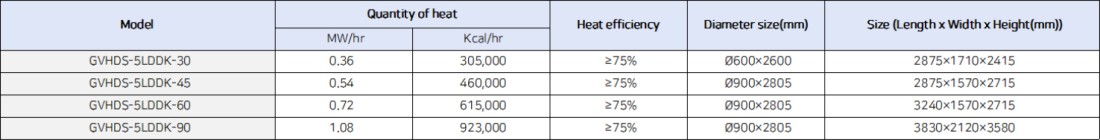

Hot Air Furnace

(using rice husks and coal)

Product specification

Product features

- Fuel supply automation: Automatically calculates the required fuel and supplies the proper amount of fuel according to the temperature.

- Constant hot-air temperature: Accurately supplies the required fuel, and the temperature difference (±0.75C°) is small.

- Good combustion and no smoke

- Prevent embers and dust from being emitted to the outside by using a cyclone

Steam Boiler

Product specification

There are some differences depending on the quality and types of fuel.

Product features

- High efficiency of the boiler (over 88%)

- Even low-quality fuel burns well.

- Various types of fuel can be used (Pellet, RDF, RPF, wood chips, livestock excretion, rice husk pellet, etc.).

- Remarkable reduction in the emissions of CO & Nox

- Long lifespan of fire plate and easy repair in operation

- Perfect ash-out, and no problem with continuous operation

- Combustion environment establishment in line with the characteristics of fuel

- AI LCD touch panel

Manufactured products

- Capacity : 1~10 Tons/hr

- Pressure/ : 1~10Kg/cm2

- Fuel : Pellet, wood chips, RDF, biofuel, coal, etc.

RDF Boiler

Product specification

There are some differences depending on the quality and types of fuel.

Manufactured products

- Capacity : 0.6, 1.2, 2.4, 3.6, 4.8, 6 Kcal/hr. (Unit : one million )

- Fuel : Pellet, wood chips, RDF, biofuel, coal, etc.

Biomess Boiler

Product specification

Product features

- Secondary combustion; maximized heat efficiency

- Fast heating and stable firepower

- Fully automatic fire-ball stability

- Easy-to-operate AI system

- Perfect combustion material treatment

Coal Boiler

Product specification

Product features

- Secondary combustion; maximized heat efficiency

- Fast heating and stable firepower

- Fully automatic fire-ball stability

- Easy-to-operate AI system

- Perfect combustion material treatment

Burner

Product specification

Product features

- It is possible to replace the conventional oil burner of boiler (steam, hot water).

- It is possible to connect directly to the rotary-kiln typed dryer.

Purpose

- Perfect combustion

- Release temperature: 950~1100℃ or higher

- CO concentration: 100ppm or lower

- PKS, wood pellet, and rice husk pellet are usable.

- AI control system